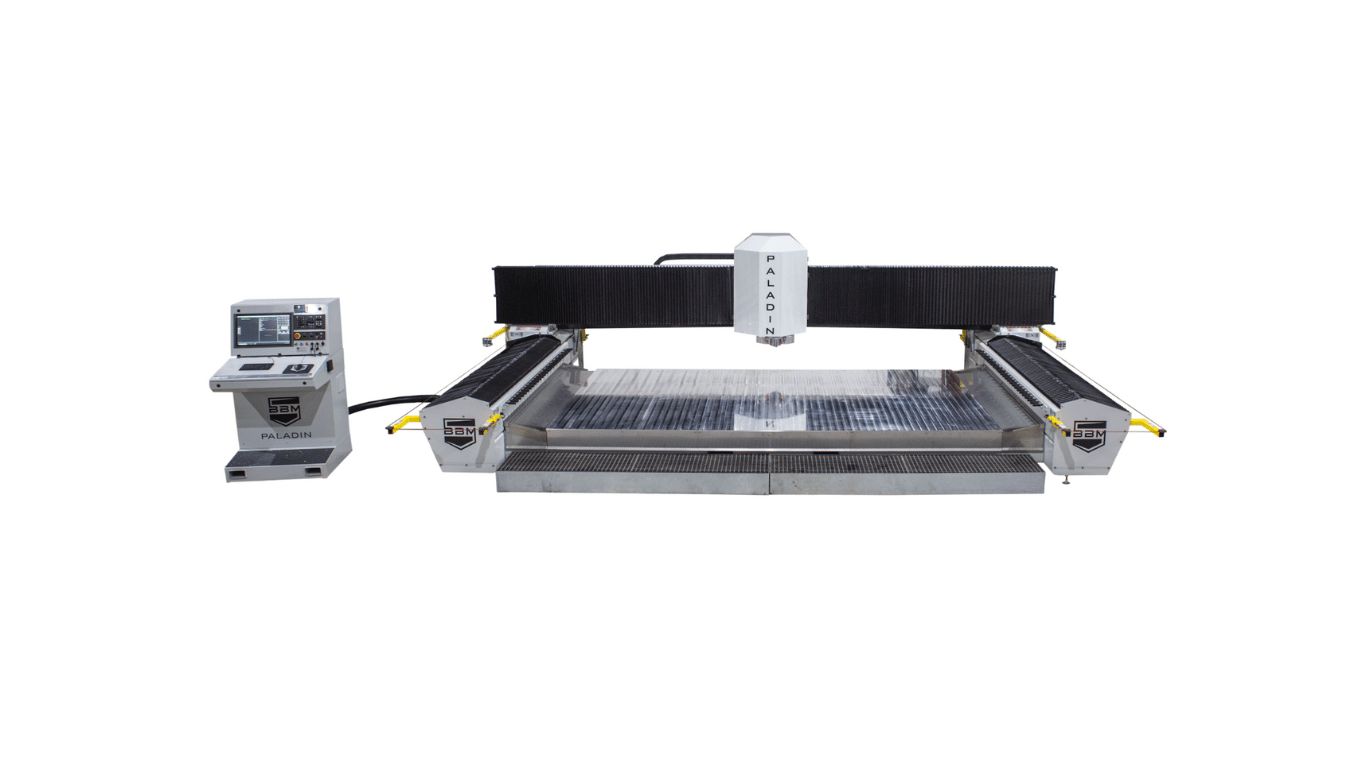

PALADIN CNC STONE ROUTER

An American-Engineered CNC Stone Router

Weighing-in at a substantial 24,000 lbs., the PALADIN’s monoblock construction is comprised of a rock-solid steel foundation. The PALADIN is an exquisite fusion of robust durability and advanced technology, delivering an unprecedented level of precision and efficiency.

The PALADIN’s state-of-the-art FANUC servo controls, precision ball screws, and expansive working table amplify productivity, while its user-friendly workstation and effortless maintenance mechanisms curtail operating costs.

Adding a PALADIN to your production force means embracing a philosophy of quality, precision and financial growth in stone fabrication.

DO MORE, FASTER

The PALADIN was engineered to remedy CNC stone router pain points fabricators have faced for decades. It’s a more powerful and user friendly machine. Program your PALADIN to begin a job with one touch of a button. Experience improved accessibility of machine components for effortless maintenance. Move your machine for easy loading of different shapes and sizes of stone. Do MORE, faster with the PALADIN.

PRECISION

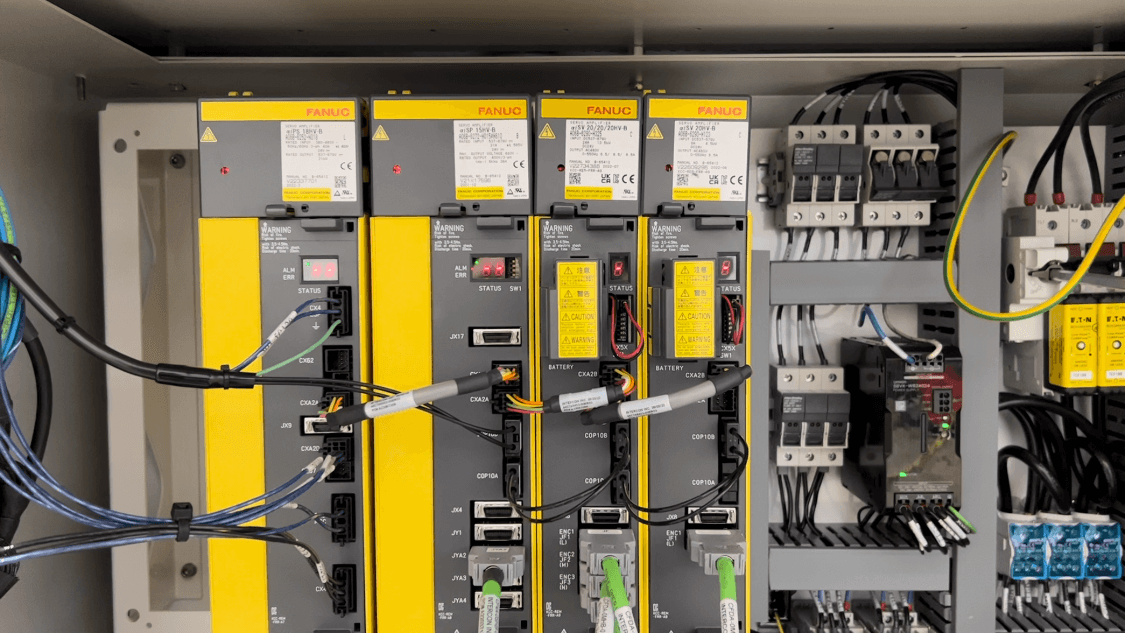

Fanuc Motion Controller

EASE OF USE

One-touch controls

Power

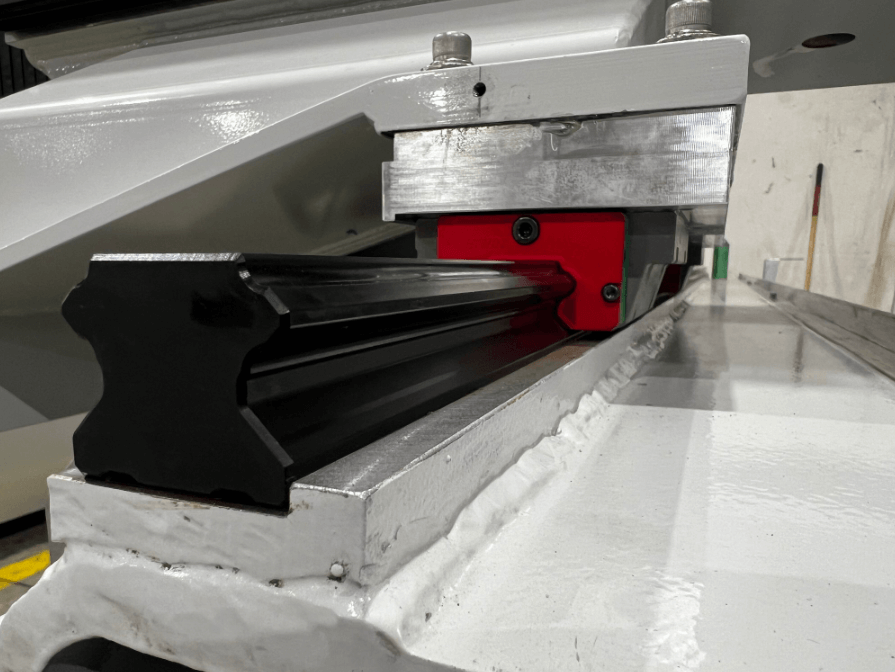

Massive Bearings

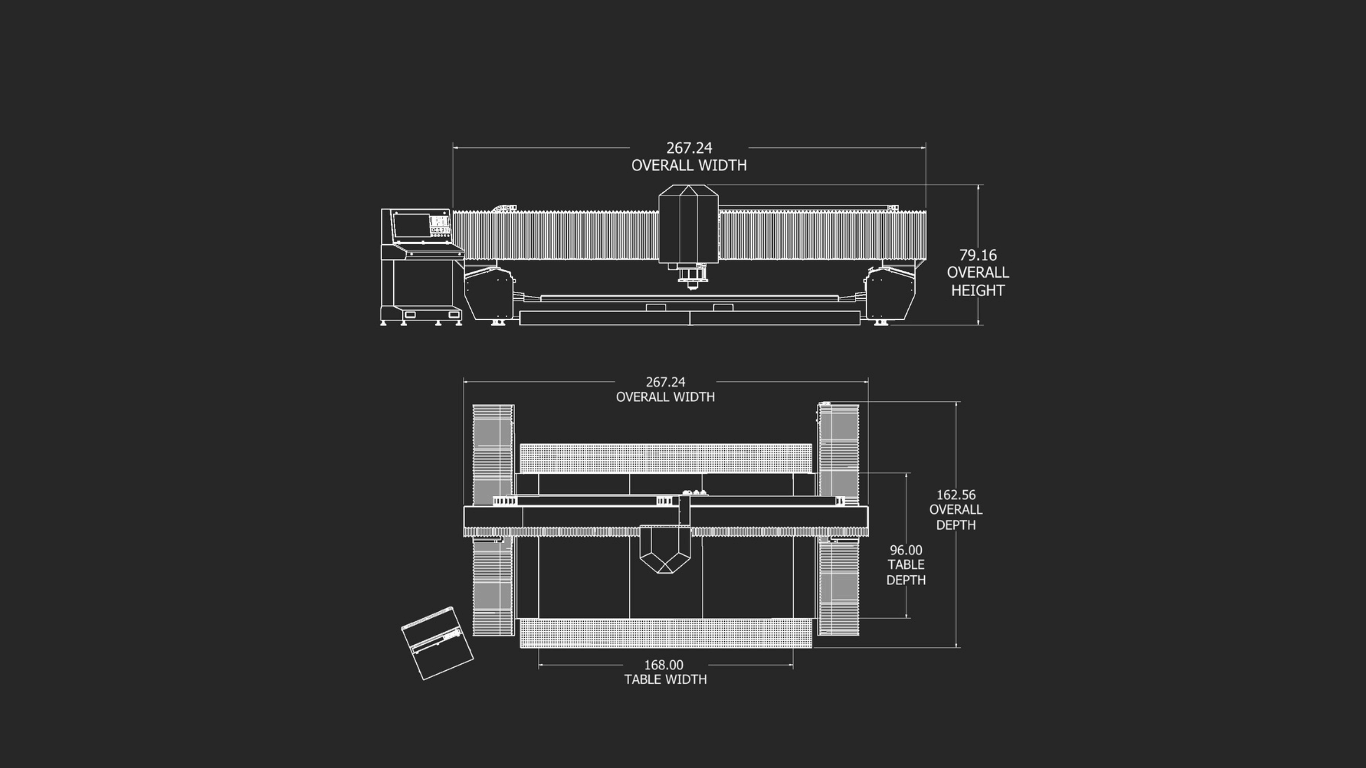

THE PALADIN GENERAL MACHINE SPECIFICATIONS

FRAME

24,000lbs of fully welded steel

Ball Screw Drive

Precision ball screws that maintain accuracy and prevent gear lashing

Cutting Table

1.5’ thick aluminum slab table

14ft x 8ft deep processing box

Workstation

BBM HMI

Spindle

Fanuc 20HP Belt drive

Rotary Union

Rapid change design completed in minutes

Bellows

Covers bearing and ways to protect from build-up

Tools

44 tool holders

Vacuum

5.5hp Liquid ring vacuum system system with hot dipped galvanized frame

Cabinets

Left or right hand option

Sensors

Digital water, vacuum, and air

WHY CHOOSE A PALADIN?

MONO-BLOCK STEEL CONSTRUCTION

It starts with steel. The PALADIN is 24,000 lbs of American iron. It’s not just the weight, it's how it’s put together. It’s built like a tank.

FANUC MOTION CONTROLS

When it comes to motion controls, BBM uses state-of-the-art Japanese FANUC servo controllers and servo drives.

PRECISION BALL SCREWS

The advantage of precision ball screws becomes more apparent as the machine ages. Ball screws do a much better job maintaining accuracy and preventing gear lashing over time.

1.5” THICK ALUMINUM SLAB TABLE

Nope, it’s not plastic— and it’s not thin. It’s built to last the life of the machine, all while providing a solid, flat surface to support pods and parts. We precision mill the table surface to ensure a truly flat surface on your machine. That’s the correct way to do it.

A REALLY BIG WORKING TABLE

The PALADIN only comes in one size— 14’ wide by 8’ deep processing box. With an aluminum slab table that large, it’s often possible to fit an entire kitchen in one batch. A bigger bed makes a big difference.

MUCH BIGGER BEARINGS

Bigger equals better when it comes to bearings— and ours are HUGE! Larger bearings ensure smooth traversing, less toroidal and axial play, and much longer life. When you start looking at the details, you will come to understand that all machines are NOT created equal. Place a quarter next to the bearings and it becomes obvious.

ALPHACAM CAD/CAM SOFTWARE

AlphaCam has been the industry leader for drawing and programing with CNC machinery since the beginning. All PALADINs come standard with AlphaCam. Choice matters, if you want to run your new PALADIN on Taglio or DDX, let our team know and we will show you the process for optioning those software suites.

21.5” WIDE TOUCH SCREEN

We spent considerable time choosing our 21.5” wide touch screen, button layout and overall ergonomics of the control unit. When you spend time looking at screens, it’s important to choose something that the operator will enjoy using. The PALADIN presents information in a clear and easy-to-understand way.

A WORKSTATION THAT MAKES SENSE

The BBM HMI (Human Machine Interface) was developed by BBM engineers to make operating the machine an intuitive logical process. It provides the information you actually need in a fresh, modern and easy-to-understand layout.

EASY ACCESS TO THE SPINDLE

The PALADIN Z-axis tool plate cover is held securely in place by rubberized retention knobs. The weight of the cover is lifted with automotive supports protecting the counter-balance system, spindle and associated hardware.

RAPID CHANGE ROTARY UNION

The rotary union is a part that will need occasional replacing. On many machine designs, this task is a serious chore. Our engineers designed the PALADIN to ensure this task can be done in minutes, not hours. User maintenance should be easy and fast.

AUTOMATED LUBRICATION SYSTEM

The PALADIN comes standard with automated lubrication, sending consistent oil to the bearings and ways. In a dusty, gritty shop, this system protects your investment, and ensures long life and peak performance. User maintenance should be minimized, if possible. Because we know you hate doing it.

LESS BELLOWS— TOTAL COVERAGE

It might seem really strange to mention covering bearings and ways with bellows. It is an important detail that some manufactures simply don’t think matters. Protecting ways and bearings is critical in a dusty, gritty stone shop.

SIMPLE IS SMART

When you look at a BBM machine, it’s interesting what’s NOT there. We have reduced the amount of cable & tracks to a minimum. We use a tray on the back of the bridge to support a much more logical cable management strategy. This efficient layout dramatically reduces cat track and cable failure over the life of the machine.

LESS CORROSION— BETTER PAINT

Our process starts with a thorough decontamination routine. Quality prep work matters. The next critical step is an application of a two-coat zinc corrosion preventive paint, followed by a top-coat of “BBM White” automotive-grade paint with a high-gloss finish.

PROTECTED WHEN SHIPPING

After your machine is built, we take great care to properly protect your investment while it’s traveling down the highway from our factory to yours. Our shrink-wrap system provides the protection your new machine deserves.

SET-UP AND TRAINING BY PROS

When you purchase a PALADIN from BBM, the price includes set-up, calibration and training at your facility. It sounds crazy to say this, but the price also includes the airfare, lodging and meals for our factory trained technicians. Our techs have years of experience installing routers and training stone shops on programming your machine with AlphaCam.

SERVICE AFTER THE SALE

At BBM, service and support are the ultimate priority. We stock all parts for the PALADIN at our factory in KY. BBM is also a technical machine service company.

VACUUM SYSTEM AND POD PACKAGE

Your new PALADIN will come with a 5.5 HP advanced vacuum system with a coolant tank to create vacuum for locking down your pods and parts. In addition to the vac system, you will also receive 24 high performance BVC Pods and four BBM manifolds with your purchase.

44 TOOL POSITIONS

The PALADIN comes standard with 44 tool holders. More holders equals more profile sets on the machine, and less messing around swapping-out tooling. Your purchase includes 44 high-quality tool holders ready for your new tooling.

TWO-YEAR WARRANTY

We are so confident in the build quality of the PALADIN that we offer a 2-year or 2000-hour parts warranty. That warranty includes sending a technician to your shop, if needed, for the first year. Let that sink in. Peace of mind and service after the sale is what BBM is all about.

HELPING STONE SHOPS INCREASE PROFITS

Today, stone fabricators across the country are reaping the benefits of the PALADIN’s performance. Multiple customers have elected to invest in more than one PALADIN, because they’ve experienced for themselves that it truly is a better built machine.